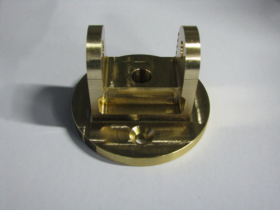

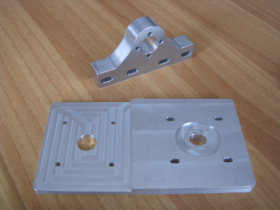

Realization of works also directly

from your digital projects.

From 2D (JPG-PDF-DGW-DXF) or 3D (IGES-STP) files

Processing also from sample pieces,

even without dimensional drawings.

Processes

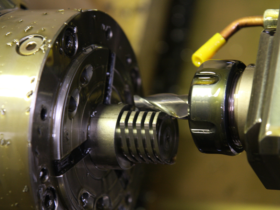

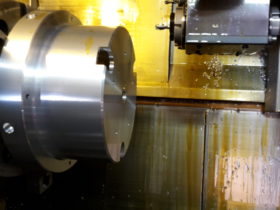

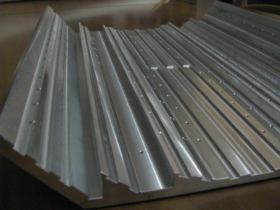

Tornitura e Fresatura CNC e tradizionale

CNC turning has always been our main commitment.

We continuously invest in new machines that are increasingly at the cutting edge of technology, precision and productivity.

To always offer a better, more precise and more convenient product.

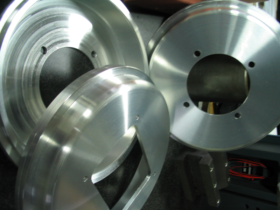

The production range goes from Ø3 mm up to Ø90 mm from bar, while in secondary turned we get up to Ø450 x 800 mm.

They are enslaved by automatic loaders to provide a large production autonomy for unmanned shifts. They accept bars from 0.5 to 3.5 m.

All machines are equipped with motorized units to complete the production cycle in a single execution. To guarantee precision and quality.

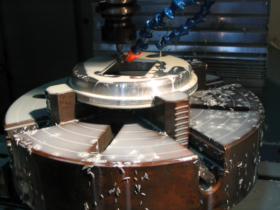

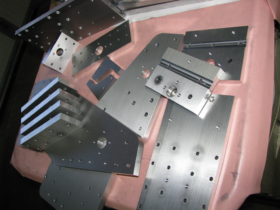

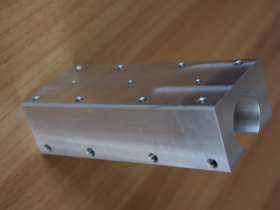

Milling, mold milling and solid prototyping

Our milling capacity is entrusted to a very high power machining center with 600 X 400 X 400 strokes.

Where we work from solid or complete semi-finished products.

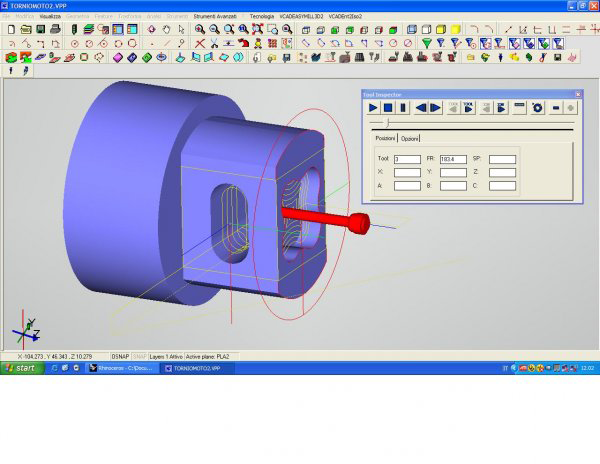

Stazione completa Cad Cam parametrico pluriasse

What is it and what does it do?

CAD is the English abbreviation of Computer Aided Design, that is, a category of software designed specifically for technical drawing assisted by the use of the PC. An example of Cad is Rhino 3D.

Cam, also in English, is the acronym for Computer Aided Manufacturing, often used in combination with CAD, it indicates the transformation of the drawing made with the PC into machine instructions understandable by the controller. Examples of Cad Cam are Aspan and Alphacam.

In summary: the PC is used to carry out the drawing with the CAD, which will provide the instructions to the Cam, which in turn will convert the information into a language understandable to the controller, through the use of a post-processor, which will provide the machine tool the “machine code” to operate the motors, manage movements, etc.

Through this powerful tool we have the possibility to run complex paths with maximum fidelity and precision; if there is a change to be made in a few minutes we are back in the car with the correction, we don’t have to start the program over again.