Torneria Cardinali is an ISO 9001: 2015 certified company.

Each year, the quality system is tested and possibly updated according to the new needs of the company.

Here are some of the control tools used by our company during the production phases

Torneria Cardinali is an ISO 9001: 2015 certified company.

Each year, the quality system is tested and possibly updated according to the new needs of the company.

Here are some of the control tools used by our company during the production phases

TECHNICAL SPECIFICATIONS

| Precision | 3μm + L/250 mm |

| Resolution | 0.5 μm |

| Optimal temperature | 18 – 22 °C |

| Operating temperature | 0 – 40 °C |

| Base | Granite |

| Travel speed | 750 mm/sec |

| Acceleration | 1750 mm/sec^2 |

| Air consumption | None |

| Pressure min. | None |

FEATURES

This Mitutoyo Electronic Height Gage includes newly developed high accuracy and high resolution ABSOLUTE linear encoder for position detection.

The QM-Height delivers a World’s Best-in-Class accuracy of +(2.4+2.1L/600)um.

Quick and easy, built-in functions measure height, inside / outside widths, inside / outside diameters, circle pitch (height components), free form surface max / min heights, and displacement by scanning measurement.

Mitutoyo’s newest innovation — the high-accuracy, high-resolution Absolute-type linear encoder — is provided on each model in the QM-Height Series for fast-and-easy position detection. Simply set the origin once, you won’t need to set again each time you power up.

The QM-Height also remembers the immediately preceding measurement (height component) and displays the difference (pitch) between the results below the measurement.

Mitutoyo’s proprietary design and software are your assurance of reliability.

A palm-sized printer manufactured by Mitutoyo. It is used to print measurement data from the digimatic signal of digital force and torque instruments.

Performs statistical analysis and can draw a histogram or D chart in addition to more complicated operations for X-R control chart. Equipped with RS-232C output and GO/NG judgment output as standard functions.

FEATURE

Precision optical measurements

Digital microscope provide a powerful, portable and feature rich solution for microscopic inspection at up to 900x magnification and 5 megapixel resolution. High quality imaging and optics, feature rich software and advanced hardware features set the microscope range apart from any comparable products.

As the inventor of the handheld digital USB microscope, now is the market leader and industry standard for digital handheld microscopes. Nowadays the digital microscope is an irreplaceable instrument for thousands of companies and professionals worldwide.

With over 150 different models the Dino-Lite range offers multiple connectivity options: USB, TV or VGA, as well as specialised illumination, such as ultraviolet or infrared, and numerous magnification ranges. A wide range of stands and accessories completes the product line-up and ensures that the Dino-Lite range offers solutions to meet the needs of the home user, through to the most demanding professional.

Details:

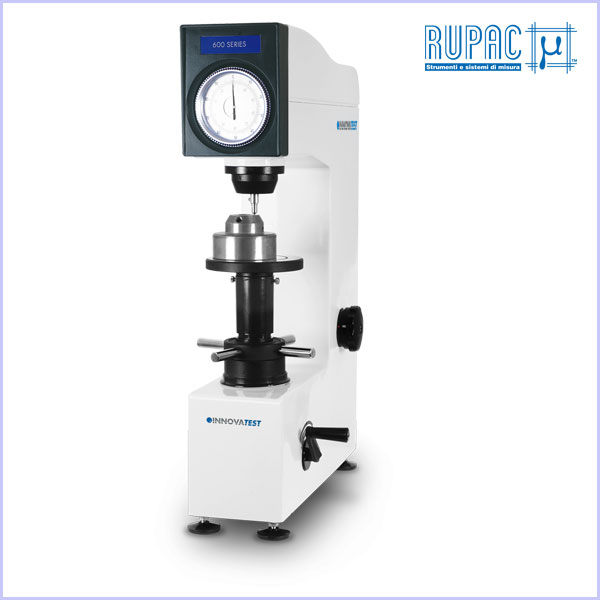

The preliminary test force has to be applied manually, followed by applying the main load by means of the lever at the right side of the hardness tester. After unloading the dial indicates the requested hardness value directly with high accuracy and repeatability.

Precision load mechism for accurate hardness measurement

Simple test force selection by turning a wheel

Rockwell hardness value on a dial

Large working space and stable shaft for large specimen

Feature & Use:

Manual testing process, no need for electric controlling

It’s steady and reliable for testing of curved surface

Precision conforms to the Standards of GB/T 230.2, ISO 6508-2 and ASTM E18

It’s suitable to determine the Rockwell hardness of ferrous, non-ferrous metals and non-metal materials.

It can be widely applied in the Rockwell hardness testing for heat treatment materials, such as quenching, hardening and tempering, etc.

Specifications:

Measuring range: 20-88HRA, 20-100HRB, 20-70HRC

Test force: 588.4, 980.7, 1471N (60, 100, 150kgf)

Max. Height of test piece: 170mm

Depth of throat: 135mm

Min. Scale value: 0.5HR

Dimensions: 466 x 238 x 630mm

Weight: Approx. 65kgs

The instrumentation of any type is governed by the internal certification protocol which imposes calibration checks spaced over time based on the nature and use concerned.

For this purpose, only certified parallel ceramic blocks ( by Accredia Institute) are used, built in accordance with DIN EN ISO 3650 in zinc oxide ceramic alloy ZrO2.